Whipps, Inc. is the market leader for high quality custom fabricated gates and water control equipment.

| Monday: | 8am – 5pm |

|---|---|

| Tuesday: | 8am – 5pm |

| Wednesday: | 8am – 5pm |

| Thursday: | 8am – 5pm |

| Friday: | 8am – 5pm |

| Weekend | Closed |

Recent News & Updates

-

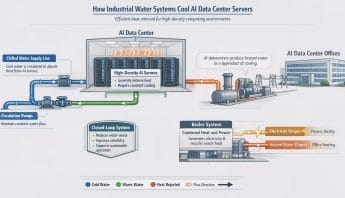

Water Control Equipment for AI Data Centers

Posted in General Whipps, Inc. News & Updates, Industrial Water Systems, Who We Serve by Brad Stevens -

How to Optimize Flow Control in Treatment Plants

Posted in Water and Wastewater Treatment Plants, Who We Serve by Whipps Inc -

The Full Range of Whipps Water Control Solutions

Posted in Custom Water Control Equipment, General Whipps, Inc. News & Updates, Our Product Series Lines by Derek Lewis -

Sluice Gates for Effective Stormwater Management

Posted in Municipal Stormwater Systems, Who We Serve by Derek Lewis -

Wrapping Up 2025 and Welcoming the Year Ahead

Posted in General Whipps, Inc. News & Updates by Derek Lewis -

Christmas Eve with the Whipps, Inc. Team

Posted in General Whipps, Inc. News & Updates by Derek Lewis -

Whipps, Inc. Featured by PausAR: Water Control Reimagined

Posted in General Whipps, Inc. News & Updates by willy@m-csi.com -

Why Aluminum Water Control Equipment Outperforms Cast Iron

Posted in Aluminum Gates, General Whipps, Inc. News & Updates, Materials by Derek Lewis -

Maintenance Tips for Water Control Equipment

Posted in Educational, Our Product Series Lines, Standards, Types of Water Control Equipment by Whipps Inc -

Critical Water Control Accessories: From Actuators to Hoists

Posted in Accessories and Systems, General Whipps, Inc. News & Updates, Products by Type by Derek Lewis

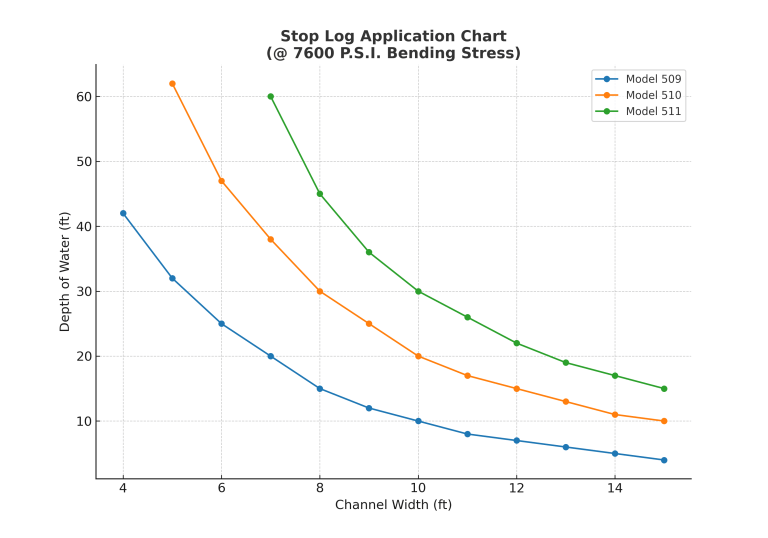

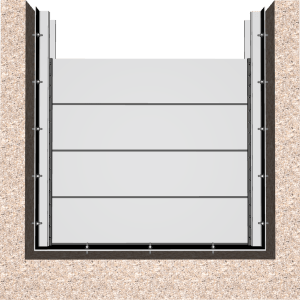

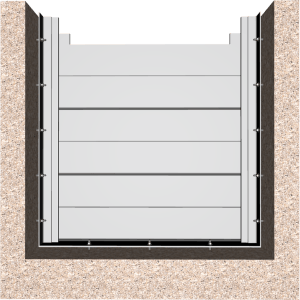

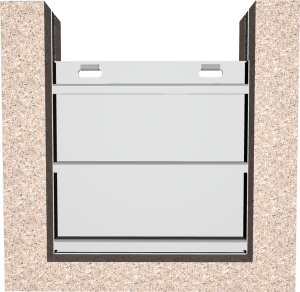

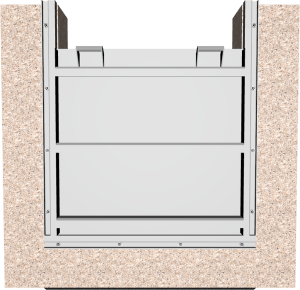

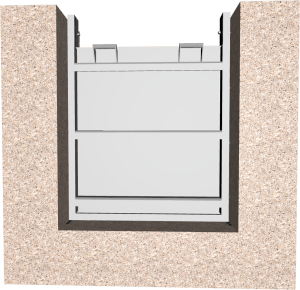

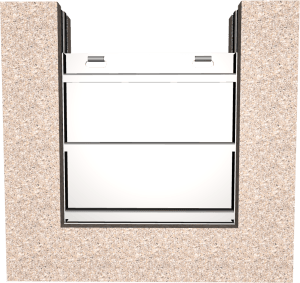

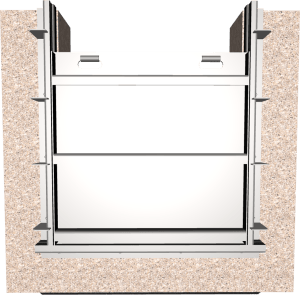

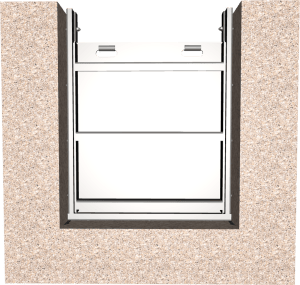

Stop Logs | Whipps, Inc.